Introduction of UIM241 series high intelligence miniature stepper motor driver

UIM241XX controller are miniature stepper motor controllers with RS232 control interface. The user device controls the UIM241XX through RS232 using ASCII coded instructions. UIM241XX controllers support open-loop and quadrature encoder (QE) closed-loop control. The UIM241XX architecture comprises communication, basic motion control, absolute position counter, QE interface and real-time event change notification modules. Embedded 64-bit calculation precision DSP controller guarantees the real-time control process. Furthermore, there are 3 optional advanced modules: Advanced Motion Control Module, QE Based Closed-loop Control Module and Sensor Control Module. With UIM241 Advanced Motion Control, selected NEMA 17/23 motors can ramp up to 4000 RPM in 0.25 seconds. UIM241 controllers can be mounted onto NEMA 17/23/34/42 series stepper motor through adapting flanges enclosure is made of die-cast aluminum to provide a rugged durable protection and improves the heat dissipation

Outstanding Parameters of UIM241 series high intelligence miniature stepper motor driver

Miniature Integral Designt

● size 42.3mm x 42.3mm x 14.5mm

● Fit onto motors seamlessly

● Die-cast aluminum enclosure

Motor Drive Characteristics

● Wide supply voltage 12-40VDC

● Max output current 2A/4A/8A, instruction adjustable

● Full step to 16th micro-stepping resolution

● Dual full H-bridge with PWM constant current control

● Accurate micro-stepping and current control

RS232 interface

● RS232 three-wire serial communication

● Max baud rate 57600 bps

Embedded DSP Microprocessor

● Hardware DSP, 64bit calculation precision

● Linear/non-linear acceleration/deceleration

● S-curve, PT/PVT displacement control

● support quadrature encoder, closed loop control

● 2 sensor input ports

● 8 programmable real-time event-based change notifications

● 5 programmable action triggered by 6 sensor events

Communication(Ambient Temperature 25)

Environment Requirements

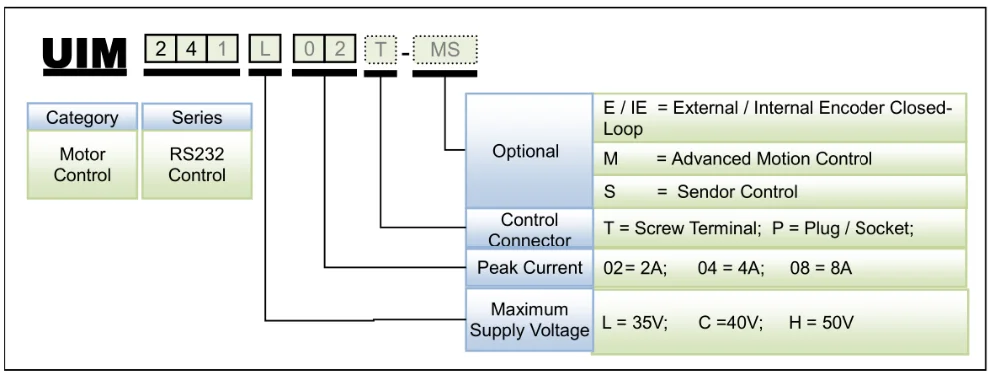

In order to serve you quicker and better, when you order UIM241 series high intelligence miniature stepper motor driver, please provide the product model number in following format.

Note:

1) Peak current is decided by maximum supply voltage (Table 0-1).

2) Default control connector is T (screw terminal) if not selected.

Table 0-1 Correspondence between Max. Supply Voltage and Peak Current

*: Custom made, please contact with salesmans before purchase.

Examples:

UIM241L02P; UIM241C04T-MS; UIM241C08P-IE

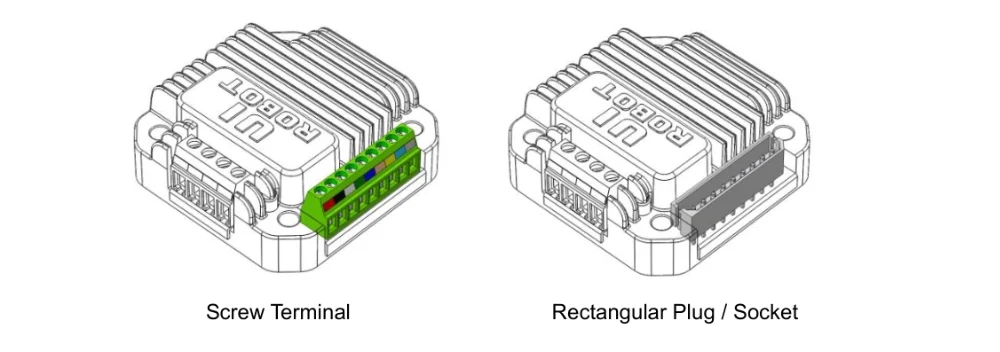

Examples of Control Connector options:

Control Terminals

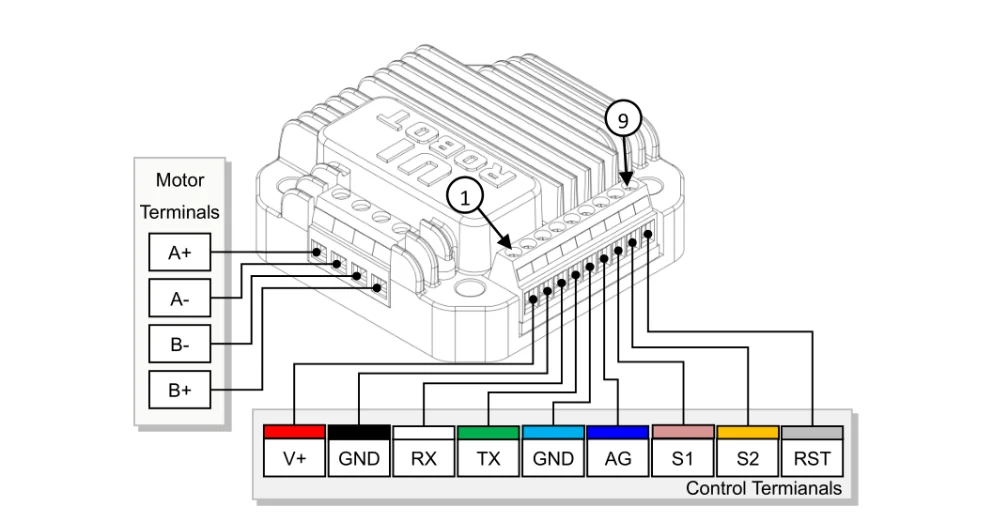

Wiring of UIM241 is simple.

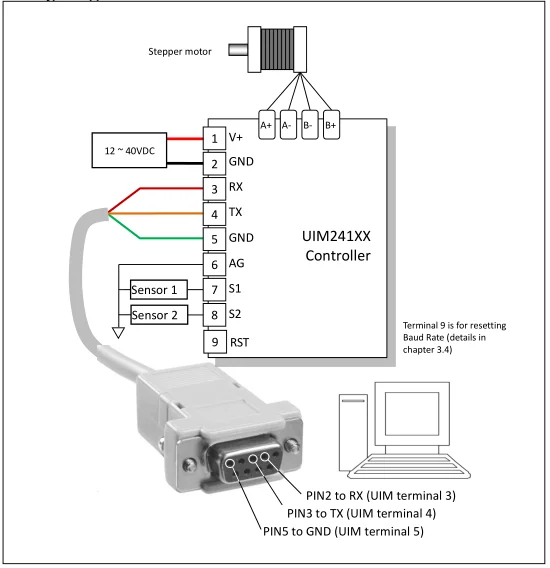

UIM241xx controllers use 3-wire RS232 interface to communicate with user devices. Terminal 3 should be connected to the RX of user device; Terminal 4 should be connected to the TX of user device; Terminal 5 should be connected to the GND of user device. An example is provided in figure 0-2. User can use an existing RS232 cable or a converted cable.

If the sensor inputs are used, make sure the signal are wired to the terminal 7 and/or terminal 8, and the signal ground are wired to the terminal 6. Furthermore, please be aware:

• User is responsible for the power supply for sensors,

• Voltage on terminal 7 and 8 must be kept between -0.3V and 5.3V

• If using an external encoder, channel A should be connected to S1; channel B to S2; GND to AG

Shanghai United Intelligence Robotics INC.(Shanghai Uirobot Technology Co., Ltd.) is a high-tech enterprise Registered in the Pudong Zhangjiang High-Tech Park, Uirobot is committed to the development of the robotic industry. Our robotic products have full independent intellectual property rights.

We advocate the philosophy of modular design and manufacture; that is, all our robots are independent modules, with each module using a unified communication protocol to communicate with other modules. In addition, the mechanical interfaces of all modules are also simple and similar to each other.

Different modules can be assembled flexibly to form robots with different functions. With user friendly features, users do not need to understand how the specific module works at the back end; they just need to combine / separate modules according to their request, which can greatly improve the versatility and flexibility of robot application and assembly.

Our lead researchers have many years of research and development experience for industrial and civilian robots.

Under Uirobot, we have developed a variety of robot components, such as wheeled and tracked mobile platforms with dedicated camera rotating heads, military-level operation control boxes, small sizes, powerful functions, intelligent stepper motor controllers, CanBus protocol-based control systems and so on. These components can be used to resolve related technical problems by themselves, or can be combined together to form robotic products with different functions.

Furthermore, we have also launched a series of stepping motor controllers. Suitable for use in both our robots and other applications, these products are characterized by small sizes and strong driving ability. With full intellectual property rights, these items are completely different from similar products on the market. With a size of just 42 x 42 x 14mm (L x W x H), these controllers have flanges that enable direct mounting onto 42, 57, 85 and 110 series stepper motors. Divided into parallel port series, UART (eg. RS232) series, CAN series etc., our ultra-miniature and micro intelligent stepper motor drivers are the only product featuring such small designs, high intelligence and high driving performance in the domestic industry.

We hope to develop new ideas and new realms in the field of robotic research and manufacturing, making our robot products as ubiquitous as home computers, and similarly playing an active role in the daily life of ordinary people. We desire to become the benchmark for robotics companies worldwide, and push the robotics industry into an advanced era.

Believing in "customers first, be creative and proactive", we will continue to provide our clients with great products and top quality services.